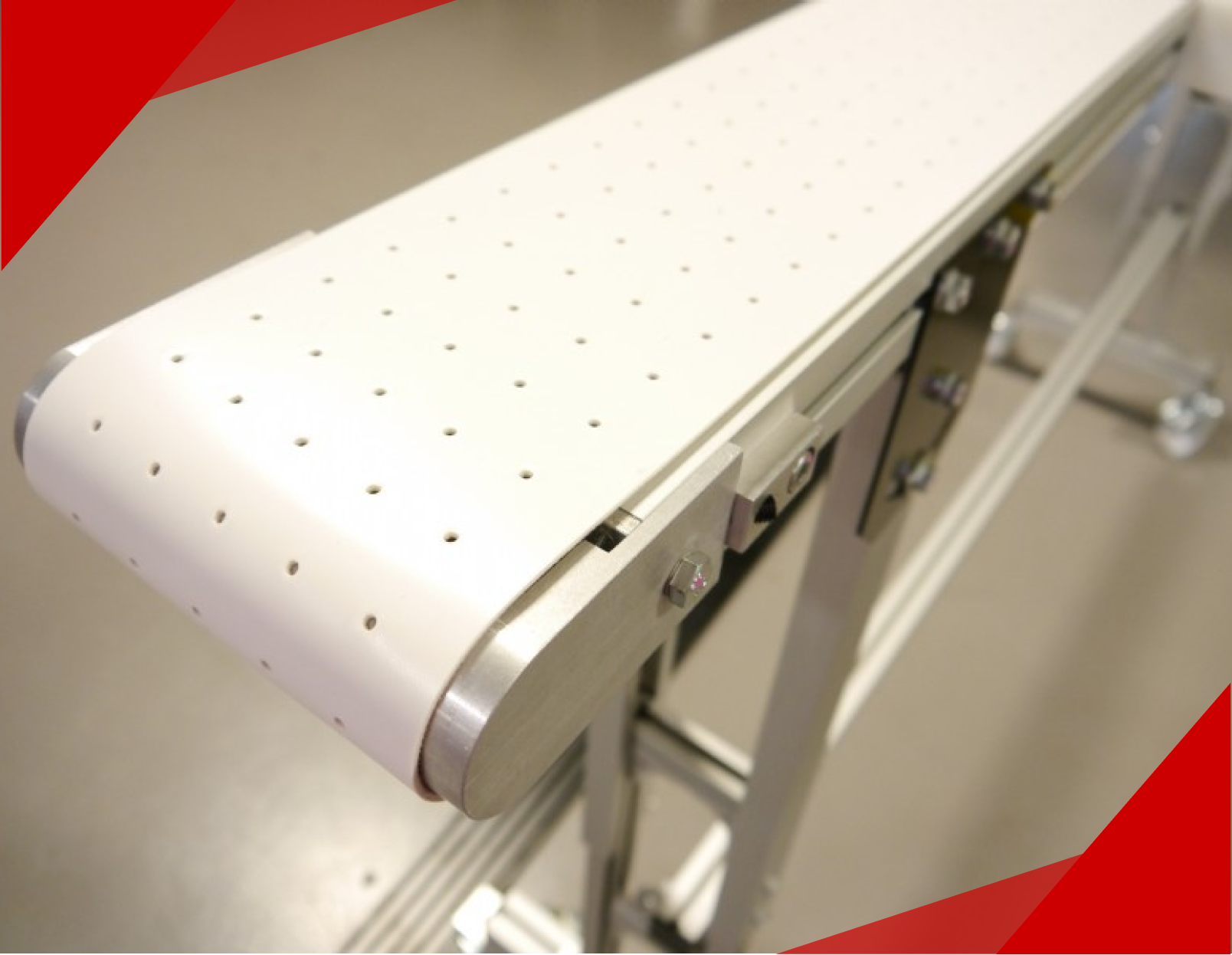

Conveying

Bulk material Storage

Aluminium Storage Silos

We design the silos individually in accordance with the customer’s requirements and specifications. Because we assemble and weld the silos on-site at our customers’ premises, we are not affected by transportation restrictions. This enables us to supply very large silos with capacities of up to 7,000 m3 all over the world, using the panel system that we have been perfecting All silo panels come in sizes that can be transported by truck or standard shipping container.

On-site assembly is performed by our own team with the use of high- tech welding equipment and tools. We do not depend on local subcontractors for assembly and welding work. Our own team then assembles and welds the silos on-site using automated high-tech welding equipment and tools that we have developed ourselves.

Stainless Steel Silos

Circular Steel Silos

Circular cross-section silos with self-supporting skirt. Can be insulated. Guarantees good durability in time and is completely waterproof and resistant to atmospheric agents. Fully hygienic with a high degree of preservation of the raw material in accordance with the rules of food hygiene.

characteristic

Silo filling system in stainless steel piping Ø 100 mm installed on an upright with lateral loading and spherical or flanged connector.

The filling pipe can be equipped with a safety device (in case of overpressure it interrupts the product flow).

Inspection window for viewing the interior, for practical prevention and maintenance.

Discharge outlet designed for the application of a vibrating bottom measuring from Ø 600 mm to Ø 1,200 mm.

Electronic weighing system at the base of the silo (indicates the content in real time and the quantity contained).

Acoustic indicator of maximum and minimum level.

Flexible Silos

Textile Silos

Uniform emptying and breathability.

Our textile SiloSac consists of a sturdy modular structure, usually bordered in galvanized or stainless steel, ideal to suit any conditions of indoor environment.

The body of the bag is made of anti-static Trevira fabric with a new geometry that ensures uniform emptying of the product by gravity.

The summit, however, is made of anti-static filtering fabric that filters clean air during filling of the silo from the tank truck. The structure, as designed, is easy to assemble and ship.

It is available in the Small version with variable capacity between 1 and 12 tons, and in the Plus version with capacity between 10 – 50 tons.

It complies with the regulations and provisions in force on the subject of technical installations with regard to safety, working conditions and health and hygiene in the workplace.