Skip to content

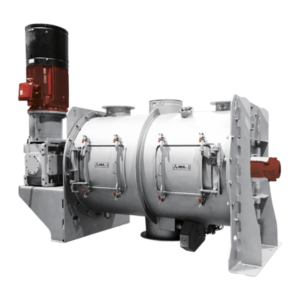

Mixing SystemsRibbon Mixers

Suitable for the following production processes:

- Mixing of powders / granules / flakes / fibers / pastes

- Wetting of solids with one or more liquids

- Heating /cooling / temperature keeping

- Keeping the product in movement (stirred bunker)

Main features

- Short mixing time

- High mixing quality

- Batches with repeatable results

- Gentle mixing

- Low maintenance

Technical features

- Batch size: from 80 to 35.000 liters (net)

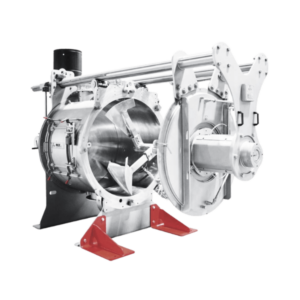

- Through “U” shaped mixing chamber

- Mixing tools: four ribbons, opposed two by two

- Material of construction: carbon steel / Hardox 450 / AISI 304 / AISI 316 / AISI 316Ti

- Inspection door on the top flat cover, complete with sfaty grid and electric block

- Discharge door with round profile, building the bottom side of the mixing chamber

- Rotor shaft with turned and coaxial ends

- Rotor shaft sealing system with packing seals and wear resistant ferrules to protect the rotor shaft, prepared for flushing with air / nitrogen

Options

- Declaration of conformity for contact with food according to regulations 1935/2004 EC and 2023/2006 EC

- Declaration of conformity Atex II 1/3D Ex h IIIB T135°C Da/Dc (Inside Zone 20, Outside Zona 22)

- Wolfram carboide coating on the external profile of the mixing ribbon

- Side mounted high speed choppers / Homogenizers

- Pneumatic sampler

- Pneumatic panel

- Heat exchanger on mixing chamber for heating / cooling processes

- Big bomb door on the whole length of the mixing chamber, to get an almost residue-free discharge in the shortest time

- Predisposition for CIP cleaning system

- Pneumatic cleaning of the mixing chamber

- Lip seal with air flushing

- Different finishes of parts in contact with product available on request.

- Easy access to the mixing chamber through an inspection door complete with safety electric lock