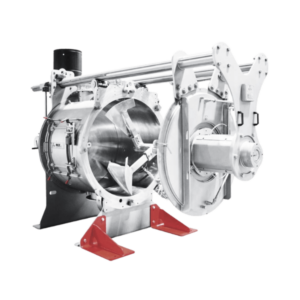

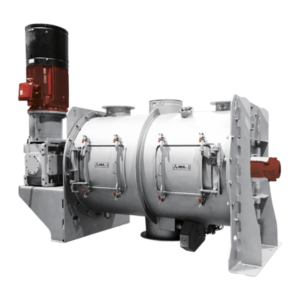

Mixing SystemsLaboratory

Ideal for the development of products and processes

• Mixing of powders / granules / flakes / fibers / pastes

• Wetting of solids with one or more liquids

• Granulation by injecting a binding liquid

• Film coating by injecting a liquid on a powder and then adding a second powder

• Heating /cooling / temperature keeping

• Drying with final moisture content <0,1% in Full Vacuum

Main features

• Short mixing time

• Extremely high mixing quality

• Batches with repeatable and scalable results

• Mixing ratio 1/100.000

• Coefficient of variation (CV): ≤ 3 %

• Low maintenance

• Functional design for installation in R&D area