Skip to content

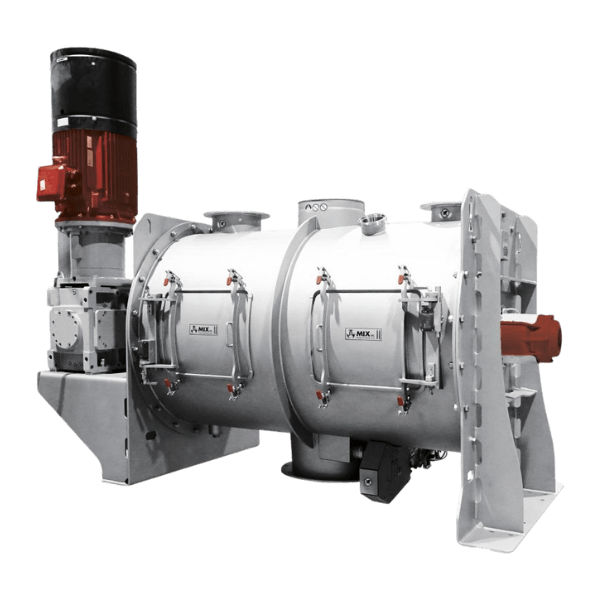

Mixing SystemsPlough Share Mixers

Suitable for the following production processes:

- Mixing of powders / granules / flakes / fibers / pastes

- Wetting of solids with one or more liquids

- Granulation by injecting a binding liquid

- Film coating by injecting a liquid on a powder and then adding a second powder

- Heating /cooling / temperature keeping

Main features

- Short mixing time

- Extremely high mixing quality

- Batches with repeatable results

- Mixing ratio 1/100.000

- Coefficient of variation (CV): ≤ 3 %

- Low maintenance

Technical features

Options

- Declaration of conformity for contact with food according to regulations 1935/2004 EC and 2023/2006 EC

- Declaration of conformity Atex II 1/3D Ex h IIIB T135°C Da/Dc (Inside Zone 20, Outside Zona 22)

- Wolfram carboide coating on mixing tools

- Liquid injection system

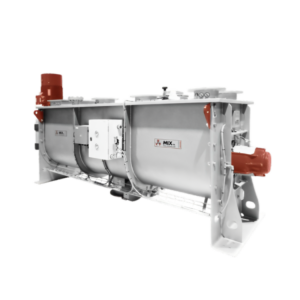

- Side mounted high speed choppers / Homogenizers

- Pneumatic sampler

- Pneumatic panel

- Heat exchanger on mixing chamber for heating / cooling processes

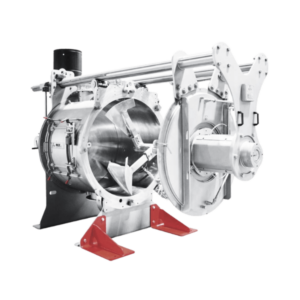

- Big bomb door on the whole length of the mixing chamber, to get an almost residue-free discharge in the shortest time

- Predisposition for CIP cleaning system

- Pneumatic cleaning of the mixing chamber

- Lip seal with air flushing

- Different finishes of parts in contact with product available on request.