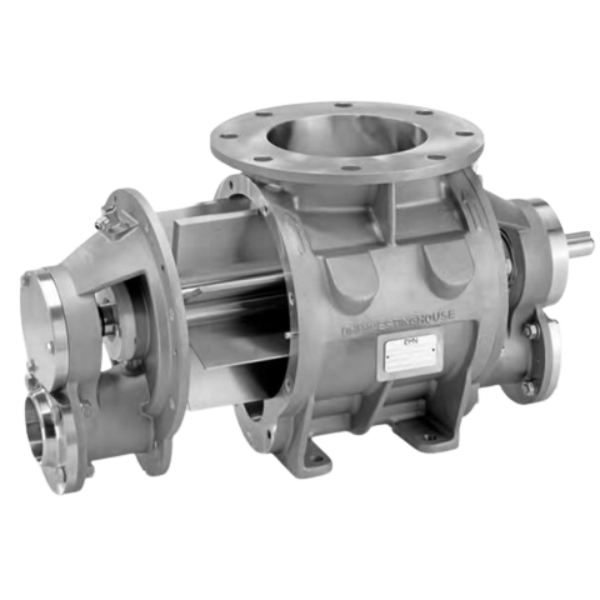

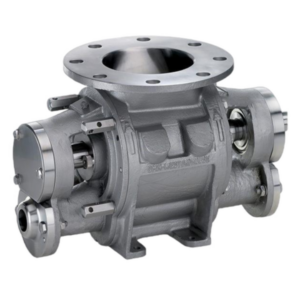

The BL-BXL Dairy blow through rotary valves have been designed for use in the food, pet food, chemical and pharmaceutical industries where very high standards apply. The Dairy valves have an official USDA certificate of acceptance for use in dairy plants and are optionally available conforming to the EC 1935/2004 directive. The construction of the valve is designed to avoid bacteriological contamination. All product contact surfaces are in food grade material and smoothly polished. The BL-BXL Dairy valves are optionally available in MZC execution with supporting bars for easy removal of the end cover and rotor without damaging the housing. The MZC valves are easy detachable in a few minutes. The BL Dairy valves are available in 6 sizes, covering a capacity range from approximately 2,5 to 58 litre per revolution at 100% filling. The BXL valves are available in 4 sizes representing a capacity range of the rotor from 5,5- 34 litre per revolution at 100% filling. The BXL size corresponds with the dimension of the inlet flange. The body and end covers are made from AISI 316 stainless steel (DIN 1.4408). The rotor is made from AISI 316L stainless steel (DIN 1.4404). For special applications internal and external mirror polishing of the valve is possible. For the BL-BXL valves tri clamp connections are also available. The shaft sealing is by means of gland packing or air purge. The standard models are suitable for temperatures up to 80 °C and a pressure up to 2 bar g. Flame proof and explosion shock resistant versions up to 10 bar g are also available.

Rotary Valve

BLOWING SEAL- BL/BXL/BXXL DAIRY

- USDA Dairy Accepted

- Versions conforming to EC 1935/2004 available

- Easy removal of the rotor for fast and efficient cleaning

- Smooth product contact surfaces in food grade material

- Rotor pockets radiused and polished to Ra=0,8 μm (150 grit)

- Rotor vanes chamfered on all edges

- Flameproof and explosion shock-resistant versions available

- Flameproof versions suitable for St2 products available

- Versions conforming to ATEX 2014/34/EU available