Reduce Fire and Explosion Risks

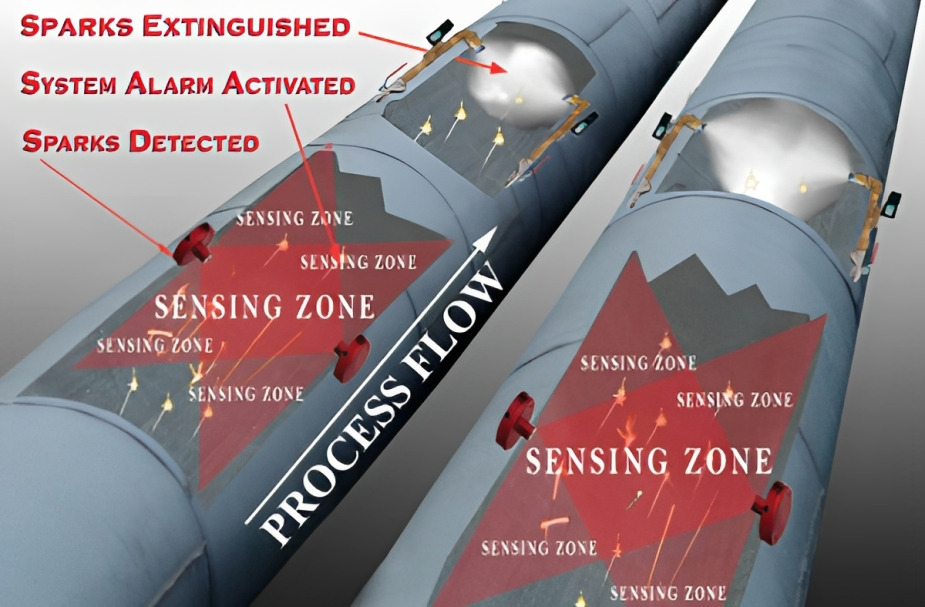

Using infrared detectors, the BS&B SparkEx Spark Detection and Extinguishing System, searches for elevated temperature particles. When hot material is detected, the BS&B SparkEx System provides many options to manage the ignition risk:

- Activate water spray nozzles placed downstream of the detection point of hot particles.

- Activate automated shut-down of the process to end the feed of combustible material.

- Provide a signal to activate other control devices shut-off valves.

The BS&B SparkEx Spark Detection & Extinguishing System operates in a continuous automatic mode with all of its critical circuits supervised to raise an immediate alarm in case of application difficulties.

Prevention Methods

- Uses highly accurate type SDN or SDD Sensors for spark detection as well as flames, and hot particles

- SDN/SDD Sensors activate control circuits connected to the automatic water extinguishing module

- The extinguishing module extinguishes sparks and hot particles

- Production continues while the BS&B SparkEx System extinguishes sparks

Industries Served

- Agriculture

- Food

- Wood

- Textiles

- Metal

- Chemicals

- Plastics

- Power Plants

- Rubber

- Recycling