SUITABLE FOR

- Filtration units

- Bins

- Mills

- Crushers

- Dust separators

- Cyclones and other industrial equipment

FOOD INDUSTRY – MALTHOUSE

Malthouses are an integral part of the food industry. This following case study will show you all risk areas, including the selection of the most suitable explosion protection designed by RSBP.

REFERENCES FROM INSTALLATIONS

DIMENSIONS :

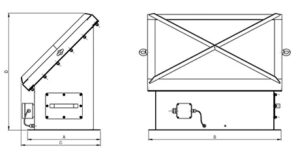

FLEX F PRO

| Type | A (mm) |

B (mm) |

C (mm) |

D (mm) |

d – diameter of screw holes (mm) | n – number of screw holes (pcs) | Weight (kg) | VMP type |

| Flex F1 PRO | 225 | 675 | 265 | 465 | 14 | 20 | 24 | 150 x 600 |

| Flex F2 PRO | 305 | 625 | 335 | 530 | 14 | 18 | 28 | 220 x 540 |

| Flex F3 PRO | 390 | 710 | 420 | 620 | 14 | 18 | 35 | 630 x 310 |

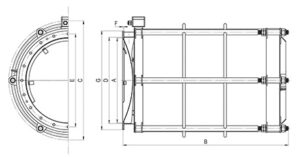

FLEX R PRO

| Type | A (mm) |

B (mm) |

C (mm) |

D (mm) |

d – diameter of screw holes (mm) | n – number of screw holes (pcs) | Weight (kg) | VMP type |

| Flex R1 PRO | 390 | 710 | 635 | 410 | 14 | 18 | 40 | 630 x 310 |

| Flex R2 PRO | 540 | 890 | 900 | 580 | 14 | 22 | 74 | 450 x 800 |

| Flex R3 PRO | 666 | 1000 | 1130 | 735 | 14 | 34 | 109 | 586 x 920 |

| Flex R4 PRO | 996 | 1198 | 1660 | 1070 | 14 | 42 | 215 | 915 x 1118 |

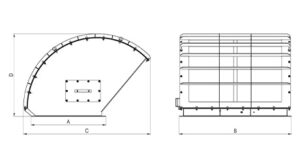

FLEX C PRO

| Type | A (mm) |

B (mm) |

C (mm) |

D (mm) |

E (mm) |

F (mm) |

G (mm) |

d – diameter of screw holes (mm) | n – number of screw holes (pcs) | Weight (kg) | VMP type |

| Flex C1 PRO | 315 | 580 | 485 | 320 | 350 | 5 | 375 | 11 | 12 | 30 | DN 300 |

| Flex C1 PRO S | 315 | 879 | 633 | 320 | 350 | 5 | 375 | 11 | 12 | 80 | DN 300 |

| Flex C2 PRO S | 445 | 1075 | 633 | 450 | 486 | 5 | 525 | 13 | 12 | 87 | DN 450 |

| Flex C3 PRO S | 505 | 1286 | 705 | 510 | 550 | 6 | 585 | 13 | 20 | 126 | DN 510 |

| Flex C4 PRO S | 625 | 1385 | 1020 | 630 | 680 | 6 | 705 | 13 | 20 | 243 | DN 630 |

| Flex C5 PRO | 815 | 2215 | 1020 | 820 | 860 | 6 | 895 | 13 | 24 | 291 | DN 800 |

FLEX F PRO

FLEX R PRO

FLEX C PRO