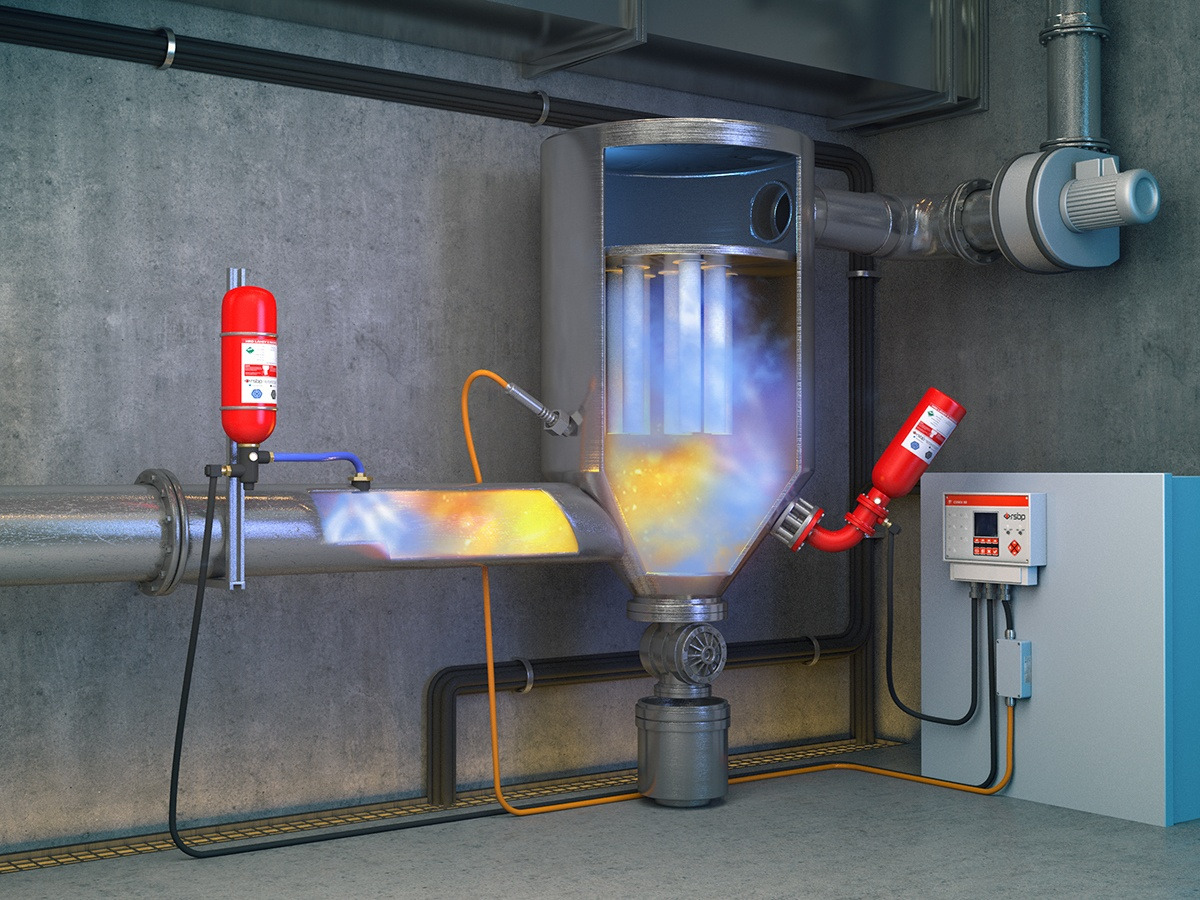

IPD Isolation System – Activation

The standard IPD Isolation System Detector is pressure driven. Mounted to the equipment in which the explosive event may occur, three pressure sensors respond to the early stages of the pressure wave that precedes the fireball in a deflagration. One of these pressure sensors is set low and provides early warning through the System Monitor of a process condition upset that may cause an unusually high system operating pressure; this is used to prevent system discharge due to non explosive process pressure excursions. When two of the three pressure sensors respond, the Isolation System is activated.

Alternative IPD Isolation System activation can be accommodated. Examples include:

- Sensors fitted to Explosion Vents such as the type MBS Burst Alert® sensor available with vent panels.

- Optical sensors (UV, IR or a combination of UV and IR).

When alternative explosion detection means are employed, the Explosion Detector is replaced by a “Detector Interface Module” that receives the sensor output and triggers the isolation Cannon(s) as well as reporting the event to the System Monitor.

Advantages

- Cannons may be installed in any orientation.

- Low mass and low reaction forces minimize installation costs for thin walled pipes and ducts.

- Intrinsically safe field wiring circuits eliminate the expense of explosion proof conduit.

- Pressure detector voting arrangement minimizes risk of activation from vibration and abnormal process pressure excursions.

- Replacement suppressant pre-packed in sealed canisters ensuring error free refit with minimal cleanup.

For applications where a pressure isolating barrier is required or the discharge of suppressant into the process is unacceptable, talk to us about Rapid Response Isolation Valves.

Service

The IPD service team is available 24/7 to support new system installation, on-site refurbishment of activated systems, to conduct the periodic audits required by NFPA 69 and to provide customer training.

Application of the IPD Isolation System

BS&B Type IPD Isolation Systems are continuously protecting common industrial process equipment including:

- Dust collectors

- Dryers

- Blenders

- Silos

- Grinders

Industries using BS&B Type IPD isolation equipment include:

- Food processing

- Grain and feeds

- Pharmaceutical

- Chemical

- Wood